CASE STUDY

The Challenge

Aerospace OEM Safran needed an experienced team to support their in-house operations with the manufacture of complex turbine components at scale.

High pressure turbine blades needed for the TP400 transporter aircraft engine are designed with a bespoke, intricate hole geometry to maximise the cooling efficiency of the ‘hot end’ part.

Due to the technical expertise and technology needed to manufacture the part, this had previously been undertaken solely by Safran. However, due to capacity constraints, Safran needed additional external capacity which was limited within the supply chain.

CASE STUDY

The Solution

Safran reached out to ELE Advanced Technologies based on our capabilities.

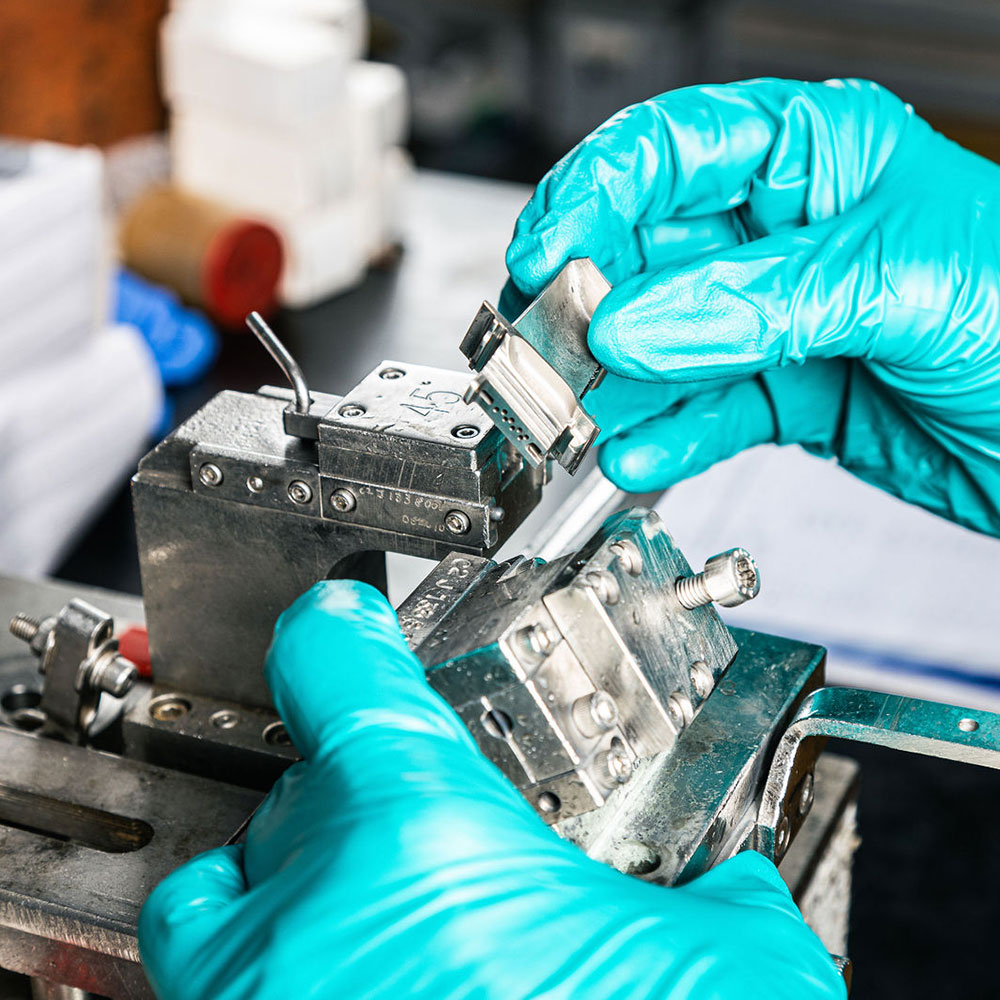

Our combination of different technologies, including stem drilling, capillary drilling, and ablative laser combined with fast-hole drilling, enable us to produce cooling holes of all shapes and sizes – from a diameter of 0.3mm up to 6.5mm.

Having such an extensive range and level of technical capabilities has resulted in ELE being one of very few companies in the world able to manufacture these complex components for Safran – on time, on budget and to a consistent quality.

CASE STUDY

What the Client Says

“The best thing about working with ELE is the breadth of their ability and expertise.

“Initially it was difficult to find a supplier that could manufacture these components for us, as the process is highly complex and technically challenging. However, ELE came highly recommended – and rightly so.

“The quality of what they produce is excellent and the level of service is great too. Their flexibility also enables us to manage any internal capacity changes effectively.

“Our reputation is based on the performance of the engines we supply, so we only work with suppliers who meet the highest standards and understand our mission to contribute to safer and more sustainable aviation.

“We’re so confident in this working relationship that we’ve recently also awarded a contract to ELE to start producing an additional, alternative turbine component for Safran.”

Philippe Goncalves

Buyer – Safran

CASE STUDY

What ELE Made Possible

Manufacture of highly complex turbine blade components at scale, to relieve internal capacity pressures for the customer, and support advancement in aircraft engine performance.